-

Posts

109 -

Joined

Content Type

Profiles

Forums

Gallery

Posts posted by RacerX69

-

-

Can't believe it. Tried my impact, then drove to my buddies for his air impact, and yet couldn't get the exhaust bolts to budge to install my HKS on. Fml

Rubbed a bunch of rust remover goop on the nutz and we'll give another attempt tomorrow. Otherwise looks like I'll need a cutting wheel

Heat it up with an oxy/acetylene torch. Turn the nuts while they are still hot.

-

Today I wept.

I wept for thousands of souls I never knew.

20 years.

WTC towers 1 and 2.

Shanksville, Pennsylvania.

The Pentagon.

Take a moment today to remember those who perished.

Never forget.

Weep for them with me.

-

I welded a bung in the side of the oil pan on my racecar to place the oil temp probe. Saved having to adapt it elsewhere.

-

Got the heads off stripped down and checked. I'm gonna try and get away with all new valves, clean up the seats and lap on the new valves.

The heads and block deck are clean and flat, a 0.001" feeler gauge wouldn't slip under the straight edge anywhere. There are some marks where the head gasket rings work against the block deck and head, but I can't feel anything with my thumbnail, so I'll clean it all up, replace all the seals and gaskets and put it all back together.

New coolant and fuel hoses, new thermostat, water pump, cam drive pulleys, etc and try for another 200,000 miles.

-

Hello:

This project has been a five year ordeal. What have we learned from this journey is that Subaru's are different cars to modify and that they require more money than I have invested in my three classic car hotrods combined which includes a blown 426 Hemi installed in a beautiful 40" Willy's coupe, My 63 Plymouth 426 Hemi sedan and my 57 Chevy with a blown L88-427 cubic inch motor!

Yeah, the Subaru is fast for a Subaru -1.5 sec to 60mph. But will require another $10K to $12K to add a Lenco transmission as the six-speed Transmission is very difficult to shift between 2nd and 3rd because of the torque load on the clutch and transmission. Thus, the quarter-mile times suffer dramatically as a result of this problem. Actually, this car will work best as a time attack vehicle with the power reduced to 700 whp. This car is also forsale with a ton of fabulous new spare parts. If interested, contact me at 916-606-6418 the selling price is $50K ($150 invested)

Grandpa’s Toy

Component & Parts list

Event: Dyno-9-2021

Location: Auburn CA

Ambient Temp: ?

Elevation: 1366 ft

Weather: Sunny

Maximum Power=MAP #1=870whp at 6100rpm and

712ft lbs. of torque@ 5200rpm,

Car: 2005 Legacy GT

Tuner: Travis (Snail Racing)

Dyno Info: Dyno-Jet, STP correction

Transmission: STI – Spec B - 6 speed,

First four gears are STI gears, fifth and sixth are much taller providing much more top end than an STI Transmission.

Cobb Quick Shift Kit, Considering purchasing a Lenco four speed

transmission!

Oil: Amsoil Synthetic 10-40wt.

Fuel: Ignite E90

Weight: Stock-3485lbs, Lightened-2635lbs,

Engine/Power Modifications:

Outfront Motorsports V4-2.5Liter Closed Deck Block Cobb AP V3 running- Speed Density

Perrin Heavy Duty Motor & Transmission Mounts

CSF Oversized Radiator, w/built-in oil cooler

Cosworth HP Oil Pump PTFE fuel system

Crawford High Pressure water pump ETS FMIC w/ 4" core

CP 8:4 pistons Supertech +1mm Inconel larger valves with matched springs

Currently using Kelford R-199-D Cams

For new motor, Elgin Custom cams will be used, 8mmTGV Phenolic Intake Spacers

ID 2000cc top feed injectors & Radium fuel rail Radium TGV Deletes

Radium Engineering Surge Tank ETS Custom 4” Cool Air System (modified by M&M)

3-Walbro 455 LPH Staged Fuel pumps Comp Turbo Cust. Twin Scroll Turbo-CT4x-6065-3bb unit

Manley Turbo Tuff I-beam rods ATI Crank Pulley

Pinned King Bearings Crawford Catch Can

STI crank in existing motor,

Manley Billet crank will be installed in new motor. Tomei Adjustable Cam Sprockets

M & M Custom 3” Down Pipe

M & M Custom 3” Exhaust, Up-Pipe T4 mount, Dual dump tubes w/twin 44mm Tial wastegates

Outfront Motorsports 1/2" head studs, ARP bolts and studs used throughout the entire motor

Current engine uses a set of ported heads. However, the new motor will use custom Heads and head work by Replika Machinsen Porting & Valve job. These heads flow 22% more than IAG Stage 4 heads.

All running gear was balanced and Cryoed & WEP Treated

IAG- EJ Competition Oil Pan, V2 Oil Pickup, Competition Baffle and Windage Tray

Driveline Modifications:

Kyb adjustable shocks & Struts Whiteline Differential Reinforced Chassis mounts

Rallytek Springs AVO End Links

Rallytek Sway Bars Torque Solutions Full Support Driveshaft Carrier Bearing

Megan Racing Adjustable Front and Rear linkage

All bushings on car have been replaced with Polyurethane bushings

Drive Shaft Shop – Custom Carbon Fiber Driveshaft

Capable of handling 1100whp.

Wheels & Brakes[/u][/b]

EBC Rotors Motul High Temp Brake Fluid

Subaru four piston front calipers RPF1-Custom Powder Coated Enkei Racing Rims

Special Compound EBC Brake Pads Toyo Red Dot High Performance Tires, or M&H Slicks

Stainless Steel Brake Lines

Interior

Kirkey Seat and cushions

Custom Rollbar

Custom Lexan Windows

Custom PLX and Innovate-Data logging Digital Guages

Element Fire Extinguishers

An extensive list.

But.

All your photos are upside down.

Oh, and if this is a for sale post, you're in the wrong neighborhood.

-

This is phenomenal! I'll be replacing my clutch and resurfacing the fly wheel soon too. Were you thinking of picking up Exedy's OEM-quality replacement KSB04 kit? Or something else entirely?

I didn't pull it apart to replace the clutch. The timing belt broke.

This car is my daily driver, since I bought it new. At 100,000 miles I replaced the timing belt and spark plugs. The car was five years old.

At around 110,000 one of the wheel bearings started getting noisy. I bought all four and replaced them.

It has taken another 11 years to get to the second hundred thousand miles. I was gathering all the usual stuff, plugs, new accessory drive belts, coolant flush, and the timing kit.

I overlooked one small detail.

The belt interval is 105,000 miles, or 105 months.

I was 27 months overdue.

So I'll likely just get a clutch disc and pressure plate at Rock Auto, and grind the surface of the flywheel on my brake lathe.

I should have the heads off in an hour or so, then I will know what needs repaired. I have a NeWay seat cutter, so if it isn't too bad I might be able to recut the seats and lap in some new valves.

-

I vanquished the Subaru Corrosion Dragon.

The original flywheel, clutch disc and pressure plate.

190,030 miles.

Probably good for another couple hundred thousand miles, but I will grind the flywheel, and replace the disc, cover, throwout bearing and pilot bearing.

-

Make sure you put anti-seize compound on those pins for reassembly.

Also put anti-seize on all bolt and nut threads.

Some of the fasteners I have removed had red thread locker on them. They felt like the threads were pulling out with the bolt.

Gonna be a lot of thread cleaning to do.

-

you sure you got all the bolts and nuts out?

Oh yeah.

The only thing holding this thing together is corrosion.

Cut my oak 2x4 down past the split and got medieval on it.

I'm winning.

Winning . . . . by Racer, on Flickr

Winning . . . . by Racer, on FlickrGraduated from tin can shims to putty knives.

Winning . . . . by Racer, on Flickr

Winning . . . . by Racer, on FlickrThe right side is pretty much free.

The left still has about 3/16" to go. Gonna let it soak and go fix lunch.

-

sometimes I just bear hug the motor and give it the beans and yank and shake the hell out of it. Usually does the job.

Also, is the engine suspended by the cherry picker/engine hoist? If the tranny is raised and the engine isn't supported by anything only the tranny, it will put all the weight of that motor on the studs. Maybe raise the engine some more.

Did you try using a pry bar or chisel and hammer to get in there? Ive pulled this motor so many times, i am anything but gentle when it comes to separating and connecting the engine to the tranny.

Just give it some man strength!

Yeah, all of that.

I've alternated between the bear hug and rasslin' method, then pulling up on the engine with the lift, stood underneath with the engine hanging free and the tranny suspended in the sling on the bridge, and pried on the only place possible at this stage, the opening where the clutch inspection cover is.

The gap I've managed to open is pretty small, and it came at a high price. I have an oak 2x4 that I've used in my shop for 30 years or more, to support stuff, form metal over, and at times to beat on things I don't want to break. I managed to beat the cases apart this tiny amount hitting the few places available, but that old oak friend has splintered to bits.

Maybe I need another oak 2x4.

I can't get anything thicker than about a five thou feeler gage at the moment, but when the gap is large enough I'll start trying prybars and other prying objects.

-

engine and tranny need to go up about an inch to clear the engine mount studs from the engine cradle. I jack the tranny up and put it on jack stands to give it the clearance for the engine to move forward. Engine can't move forward if the engine mount studs aren't clear.

Thanks.

As I mentioned, the front of the tranny is supported by a bridge that sits on the strut towers. Same as a jackstand, only better. I can raise or lower the car on the lift at will, and it won't fall off of the jackstand. I can wrestle the hell out of the engine and it won't fall off of the stand.

I did fail to mention that I had the whole thing about 2 inches higher than it needs to be to clear the motor mount studs, sorry, eh?

I just made some shims from soup cans and slipped them in above the dowel pins. Gonna try and wrestle it some more after another soak in penetrating oil.

-

So I'm pulling the engine in my 05 2.5i goon. I want to leave the tranny in the car, have everything unfastened and removed that needs to be done. The tranny is hanging on a bridge from the strut towers and still connected to the rear mount.

I have the engin loose, it wiggles up and down, and can measure about a 0.005" gap. I've soaked the entire mating surface with penetrating oil. The two studs at the lower attachment points appear to be free, I tried to remove them, but no room for a stud puller, and double nutting resulted in no joy.

It appears that the two dowel pins about halfway up each side are where it is hanging up. When I speak the area with penetrating oil, then wiggle the engine up and down, it looks like some schmutz is working out, but I've been working on this since last Sunday.

There is no place to pry the cases apart, so it has me stumped.

Ideas anyone?

Subaru Engine Removal by Racer, on Flickr

Subaru Engine Removal by Racer, on Flickr Subaru Engine Removal by Racer, on Flickr

Subaru Engine Removal by Racer, on Flickr -

Looks like the reman engine is a no go. Eight weeks lead time.

Eight weeks?

In eight weeks the engine could be rebuilt eight times.

Sheesh!

I'm gonna pull the engine and open it up, see what I have. Just need to find a machine shop that knows how to deal with the uniqueness of a boxer.

-

Looking at remanufactured longblock assemblies. Saw this:

Anyone ever hear of them?

-

A few of mine.

Death Valley Overlook by Racer, on Flickr

Death Valley Overlook by Racer, on Flickr 177,000 Miles And Counting by Racer, on Flickr

177,000 Miles And Counting by Racer, on Flickr 177,000 Miles And Counting by Racer, on Flickr

177,000 Miles And Counting by Racer, on Flickr-

1

1

-

-

Yes they do. I have a set of the 1500 grinds on my N/A. I thought they may be able to give a competent machine shop though.

Ah, I see, doh!

Sorry, eh?

-

You might reach out to delta cams in Tacoma.

Thanks, but Delta Camshaft focuses on cams.

I've used them dozens of times over the years. A nice lumpy bumpstick for the 20R in my my Toyota Hilux, and I've lost count of how many I have gotten from them when building L series engines for my race car. They also regrind the cam followers for the L series engine.

Great resource.

-

Hey everyone, long time, no post. Lots of overtime at The Big Shed.

Oh, and happy Covid, eh?

Anyway, my 05 Legacy 2.5i wagon is nearing 200,000 miles. I have gathered all the stuff to do a major service, cam belt and associated stuff, oil, filter, even sprung for new Enkei RPF1 wheels and BF Goodrich tires.

Enkei RPF1 by Racer, on Flickr

Enkei RPF1 by Racer, on Flickr New Shoes For The Goon by Racer, on Flickr

New Shoes For The Goon by Racer, on FlickrI was getting excited about giving the Goon a full detail in and out, and head for another 100,000 miles.

Yesterday morning I'm heading into the city for another Friday at The Big Shed. The odometer had just turned 199,000 miles as I pulled away from the house. It is about 30 miles to work, and I had just rounded the curve from I-5 South to SR-526 West, accelerate up the hill, shifted into 5th and as I was passing under the Evergreen Way overpass at about 75, the car felt like it just shut off.

Nothing.

Momentum kept the car moving forward, still in gear.

The cruise control light came on and started blinking.

Then the gong sounded and the CEL light came on, then all the other idiot lights.

I turned on the 4 way flashers, and coasted to a stop just past the overpass. Got a flashlight and had a look under the hood. Nothing looked out of place. Got back in and tried the starter, but it was not easy to hear over the noise of passing commuters whizzing by.

Called a tow, took it home and drove the Ram to work.

Last night I connected the scanner and it had a P0340 cam sensor circuit code set. Checked the sensor, and harness, all OK.

Pulled the left cam belt cover and found the belt had failed.

99,030 Miles by Racer, on Flickr

99,030 Miles by Racer, on FlickrBummer.

I replaced the first belt at 100,000 miles, the recommended interval is 105,000. This belt had 99,030 miles on it.

The engine turns over freely, and I see this is an interference engine, so it looks like rebuild time.

Can anyone recommend a shop in the Puget Sound region that is fluent in Subaru engines for the machine work? I don't need a repair shop, only a machinist. I will be pulling and stripping the engine myself, and will take the shortblock to get the machine work done.

I read the list in the sticky, and didn't see anything, only repair shops, who will only be middle men.

Thanks in advance for any recommendations.

-

Yeah I just have the cheap gun that comes with my 110psi walmart compressor.

Wrapped the metal tip with a ton of pipe tape, eventually one popped out..now to figure out how to get the second piston out without the seal of the first one.

Also, eye and ear protection folks. That piston popping out sounded like a gun going off in front of my face.

Edit re: how to get the second piston out: push the first back in a little. Hold it there with a brake piston spreader/compressor tool. Second comes out.

I use a piece of wood placed between the pistons. When shop air is applied to the caliper both pistons should come out.

Try doing a 4 or 6 piston caliper sometime.

-

Decided to try and get the JDM double DIN installed. Got everything put together, and no sound from the driver rear speaker. Checked all the wires, everything is plugged in and signal is good at the harness; plugged the factory radio back in, still no sound; swapped speaker with a known good speaker, still nothing. I'm at a loss for what to look for next.

Any ideas?

Look for an open in the harness between the radio and the speaker using an ohmmeter.

-

Rebuilding brake calipers - compressed air not doing the trick to push out the pistons. Can't get a good seal. Any tips?

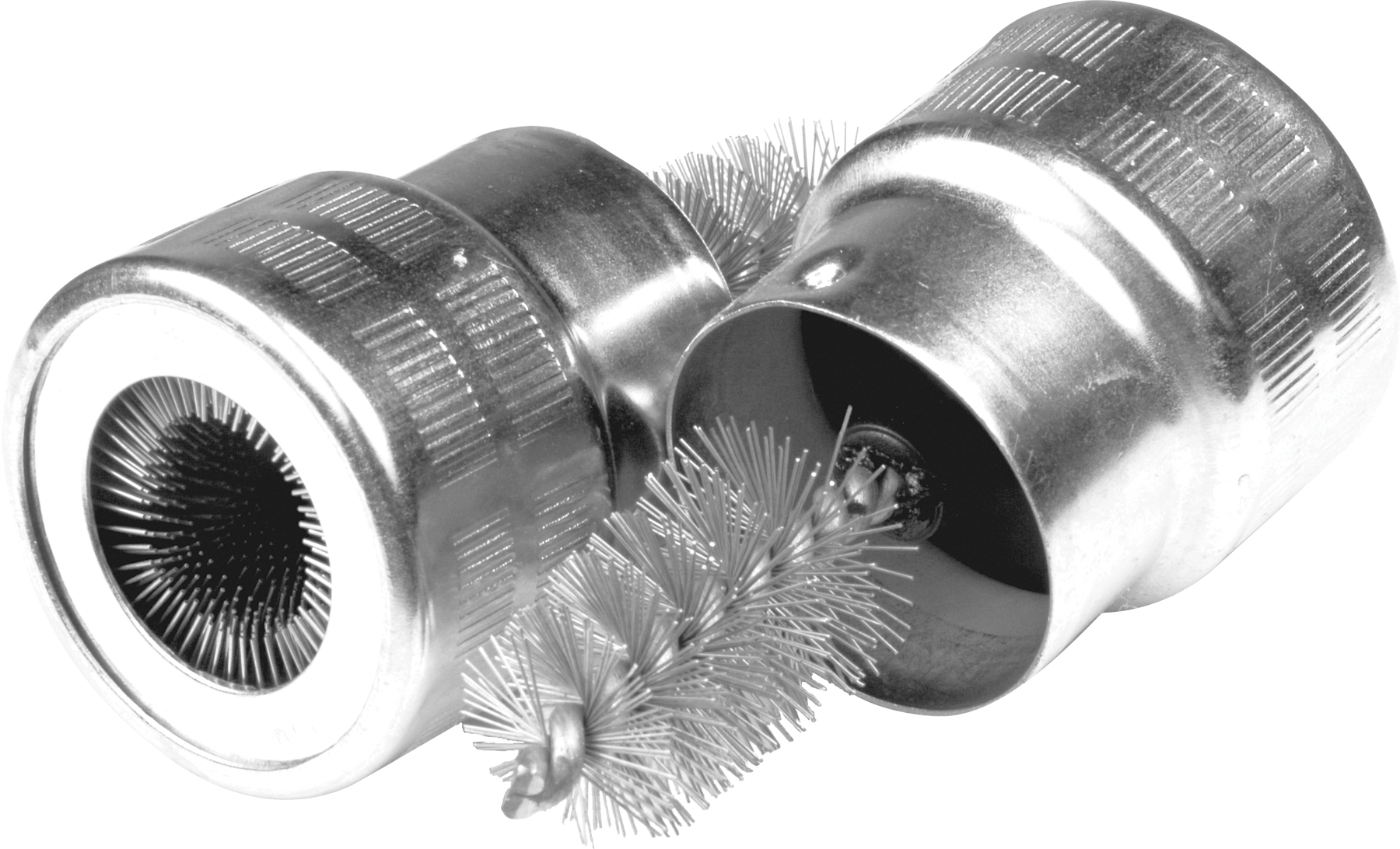

I use one of these, with the rubber tip.

-

Best thing I found for cleaning battery terminals and battery cable connectors is cleaner that's used for PVC plumber tubes, the purple colored one.

This is what I use for cleaning battery terminals and posts. (Actually I've worn out a few)

Is there a properly conductive grease than that can be used on connectors? I thought the idea is to keep them clean and dry.

Is there a properly conductive grease than that can be used on connectors? I thought the idea is to keep them clean and dry.Been using this on all my battery terminals for over 45 years. Never had any problems with corrosion or cranking/starting troubles. Cover all contact points, and all exposed terminal and post metal to keep it from oxidizing.

-

Lift kit for the wagon so those rocks just fly under you?

I'd have to get it up pretty high. I live up in the Cascade foothills, and there are several rock quarries nearby. The dump trucks throw rocks from their tires, and even when they are going the opposite direction on the highway the gravel flies.

There is no escaping them.

I'm on my 4th windshield, and it needs replaced again. It got broken just after I replaced it last time, a rock came off a dump truck going the opposite direction. I saw the rock coming, and was helpless to do anything but flinch.

It pissed me off so much I refused to replace it until a cop stops me and forces the change. And so far I haven't been stopped for it.

Maybe I should put vinyl film on the windshield too.

-

New front rotors and brake pads on my Legacy wagon today. The car has 177,000 miles on it, and I turned the rotors 4 years ago at about 110,000 or so when I replaced the pads on all 4 calipers.

The fronts began exhibiting signs of warping recently, and had no more meat left for another pass on the brake lathe. For just a bit over $16 each for the replacement rotors, and $17 for the pads it was easy enough on the wallet.

Should be good for another 110,000 miles or so.

Fumoto Oil Drain Valve - anybody using one?

in Fourth Generation Legacy (2005 - 2009)

Posted